PRODUCTS

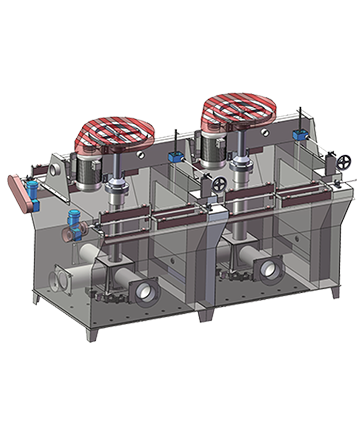

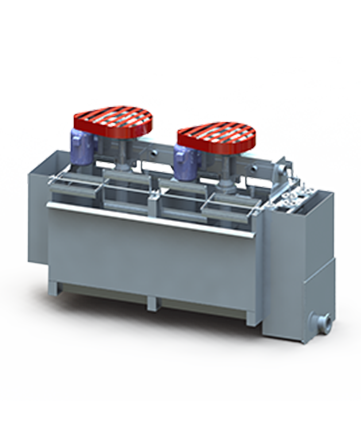

Flotation Cells

Flotation Cells

Tufekcioglu designed a new flotation cell for the first time in Turkey in cooperation with Tubitak-University and got a patent for this machine.

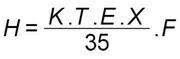

Volume Calculation of Flotation Cell

Volume of flotation cells is calculated with the following formula according to the froth skimming time (T), pulp solid percentage (P) and the specific weight of the mineral determined in the laboratory tests and the plant capacity (K).

Volume of flotation cells is calculated with the following formula according to the froth skimming time (T), pulp solid percentage (P) and the specific weight of the mineral ( )* determined in the laboratory tests and the plant capacity (K).

H: Total cell volume for coarse flotation, m3

K: Capacity, dry ore tons/hours

T: It is found by multiplying the time scale multiplier given in the Table below by the laboratory flotation time (minutes).

E: Air volume factor, 1.18.

* Generally, 15% of the cell volume is considered as air.

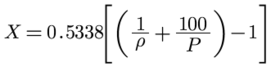

X: It is calculated as follows according to the specific gravity of the ore and the pulp solid’s %.

F: It is a factor that the cell producer will determine which usually varies between 1.1 and 1.25.

The total conventional (prismatic) cell volume for the coarse flotation found by the above formula is divided by the number of required cells specified in the Table below, and the volume of each cell is calculated.

Conventional Flotation Cell Calculation Chart

Mineral | Lab.Flot. Time (minutes) | Time scale multiplier | Min. Number of Cells | Max. Number of Cells |

Copper Sulfide (c.pyrite, bomite, chalcosine, fahlerz, etc.) | 6-8 | 2,1 | 12 | 20 |

Barite | 4-5 | 2 | 4 | 10 |

Glass sand impurities (hematite, biotite, etc.) | 3-4 | 2,3 | 4 | 8 |

Zinc (Sphalerite) | 5-6 | 1,8 | 6 | 12 |

Feldspar impurities (hematite, biotite, sphene, rutile, etc.) | 3-4 | 2,6 | 4 | 10 |

Fluorite | 4-5 | 2 | 5 | 12 |

Coal | 2-3 | 1,6 | 3 | 6 |

Lead (Galena) | 3-5 | 1,8 | 4 | 10 |

Molybdenum (Molybdenite) | 6-7 | 2,6 | 12 | 20 |

In recent years, while determining the number of large volume tank cells produced, it is mandatory to consider the possibility of short-circuiting the pulp as well as the required froth surface area depending on the ore input grade.

Tufekcioglu started to serve as the only Flotation Cell manufacturer in Turkey in 1999. While developing the classical style flotation cells with its long years of experience and R&D studies in the sector, it also produces new and Tufekcioglu patented large-volume tank cells.